Persisting in "High good quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with shoppers from each overseas and domestically and get new and previous clients' high comments for

Brass Butt Weld Knife Gate Valve

, Female Threaded Pipe Fitting

, Temperature Measuring Brass Ball Valve

, We value your inquiry, For more details, please contact us, we will reply you ASAP!

2017 Latest Design Brass Angle Radiator Valve -

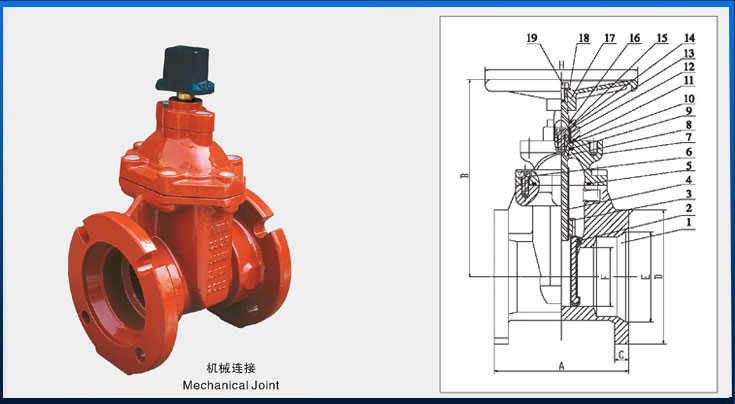

Mechanical Joint Ends NRS Resilient Seated Gate Valves-AWWA C509-UL/FM Approval – Kingnor Detail:

Name:Mechanical Joint Ends NRS Resilient Seated Gate Valves-AWWA C509-UL/FM Approval

1.Standard: Conforms to AWWA C509

2.Material: Ductile Iron

3.Normal Pressure:250PSI/300PSI

4.Size: 2″-16″

| Product details: |

| 250PSI AWWA C509 Iron Body Mechanical Joint Ends Resilient Wedge Gate Valves |

Bolted Bonnet ?Non-Rising Stem ?Resilient Wedge ?MJ Ends

250 PSI/17.2 Bar Non-Shock Cold Working Pressure

CONFORMS TO AWWA C509 |

|

|

|

|

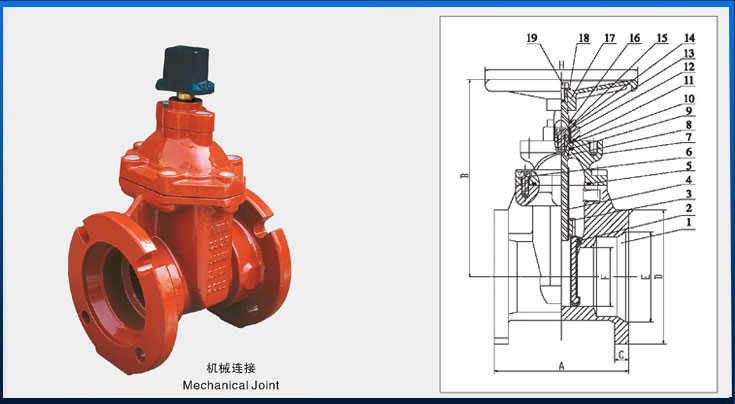

PART |

SPECIFICATION |

|

1.

|

Valve Body |

Ductile Iron ASTM A 536 |

|

2.

|

Resilient Wedge |

Ductile Iron ASTM A 536/EPDM ASTM D 2000 |

|

3.

|

Wedge Nut |

Bronze ASTM B 584 UNS C83600 |

|

4.

|

Stem |

Bronze ASTM B 150 UNS C61400 |

|

5.

|

Bonnet Gasket |

EPDM ASTM D 2000 |

|

6.

|

Bonnet Screw |

Alloy Steel ASTM A 574M Zinc Plated |

|

7.

|

Bonnet |

Ductile Iron ASTM A 536 |

|

8.

|

Stem Primary O-Ring |

EPDM ASTM D 2000 |

|

9.

|

Stem Thrust Washer (lower) |

Bronze ASTM B 584 UNS C83600 |

|

10.

|

Stem Thrust Washer (upper) |

Stainless Steel ASTM A 276 UNS S41000 |

|

11.

|

Gland Seal O-Ring |

EPDM ASTM D 2000 |

|

12.

|

Stem Seal Bushing |

Bronze ASTM B 584 UNS C83600 |

|

13.

|

Stem Secondary O-Ring (2) |

EPDM ASTM D 2000 |

|

14.

|

Gland Flange |

Ductile Iron ASTM A 536 |

|

15.

|

Gland Flange Screw |

Alloy Steel ASTM A 574M Zinc Plated |

|

16.

|

Stem Ring Wiper |

EPDM ASTM D 2000 |

|

17.

|

Square Operating Nut |

Cast Iron ASTM A 126-B |

|

17A.

|

Handwheel (Optional) |

Ductile Iron ASTM A 536 |

|

18.

|

Flat Washer |

Carbon Steel Zinc Plated |

|

19.

|

Screw |

Alloy Steel ASTM A 574M Zinc Plated |

|

Size

|

Dimensions

|

Bolt

Circle

|

Flange

Holes

|

Turns

To Open

|

Weight

|

|

A

|

B

|

C

|

D

|

E

|

F

|

H

|

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

Lbs.

|

Kg.

|

|

3

|

80

|

8.0

|

203

|

12.7

|

322

|

0.94

|

24

|

7.7

|

196

|

4.9

|

126

|

3.1

|

80

|

10.2

|

260

|

6.19

|

157

|

4

|

10.8

|

43

|

20

|

|

4

|

100

|

10.0

|

254

|

13.5

|

344

|

1.00

|

26

|

9.1

|

232

|

6.0

|

153

|

3.9

|

100

|

10.2

|

260

|

7.50

|

191

|

4

|

13.0

|

70

|

36

|

|

6

|

150

|

11.5

|

292

|

17.4

|

441

|

1.06

|

27

|

11.1

|

283

|

8.1

|

206

|

5.9

|

150

|

14.8

|

375

|

9.50

|

241

|

6

|

15.7

|

112

|

51

|

|

8

|

200

|

11.5

|

292

|

20.8

|

529

|

1.12

|

28

|

13.4

|

340

|

10.3

|

261

|

7.9

|

200

|

14.8

|

375

|

11.75

|

298

|

6

|

17.3

|

170

|

77

|

|

10

|

250

|

13.0

|

330

|

24.2

|

614

|

1.18

|

30

|

15.7

|

400

|

12.3

|

313

|

9.8

|

250

|

15.7

|

400

|

14.00

|

356

|

8

|

21.4

|

267

|

121

|

|

12

|

300

|

14.0

|

356

|

27.6

|

700

|

1.25

|

32

|

18.0

|

456

|

14.4

|

367

|

11.8

|

300

|

19.7

|

500

|

16.25

|

413

|

8

|

25.3

|

388

|

176

|

|

14

|

350

|

15.0

|

381

|

31.8

|

807

|

1.38

|

35

|

20.3

|

516

|

16.5

|

420

|

13.8

|

350

|

19.7

|

500

|

18.74

|

476

|

12

|

30

|

550

|

250

|

|

16

|

400

|

16.0

|

406

|

34.3

|

870

|

1.46

|

37

|

22.6

|

573

|

18.6

|

473.5

|

15.7

|

400

|

19.7

|

500

|

21.22

|

539.5

|

16

|

34

|

726

|

330

|

|

|

|

Product detail pictures:

Related Product Guide:

Leaky pipes may be causing more damage to your home and wallet than you realize | Grooved Flange Adaptor

Preparing the adaptor – LVSA readies for SLS debut | Flange Adaptor

We have advanced equipment. Our products are exported to the USA, the UK and so on, enjoying a good reputation among customers for

2017 Latest Design Brass Angle Radiator Valve -

Mechanical Joint Ends NRS Resilient Seated Gate Valves-AWWA C509-UL/FM Approval – Kingnor, The product will supply to all over the world, such as: Oman

, Adelaide

, Nicaragua

, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.