Product Detail

Product Tags

Related Video

Feedback (2)

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for

Sanitary Tri Clamp Adaptor Butterfly Valves

, Rigid Coupling

, Black Malleable Pipe Fitting

, To acquire a consistent, profitable, and constant growth by getting a competitive advantage, and by continuously increasing the value added to our shareholders and our employee.

Well-designed Thread Swing Check Valve -

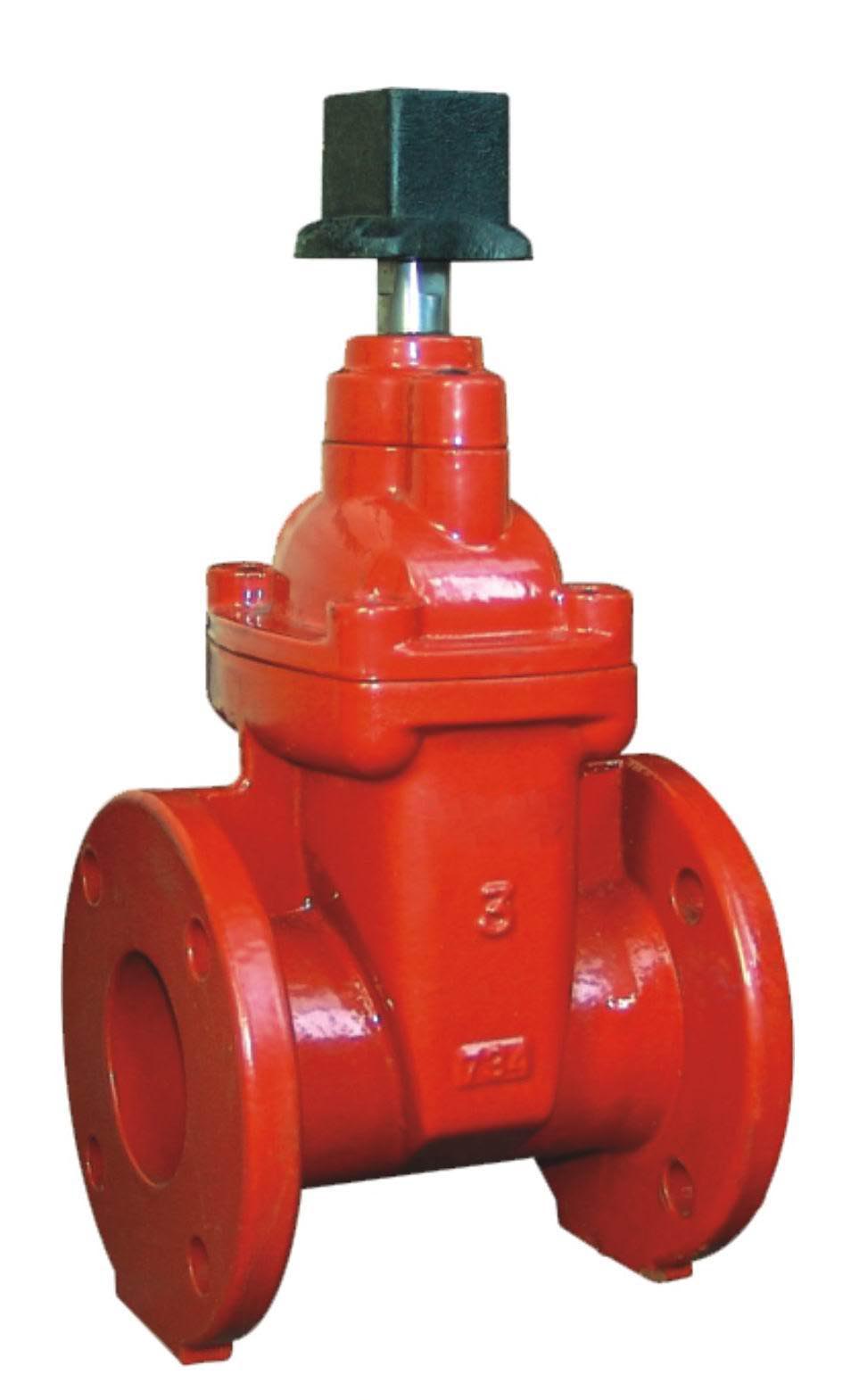

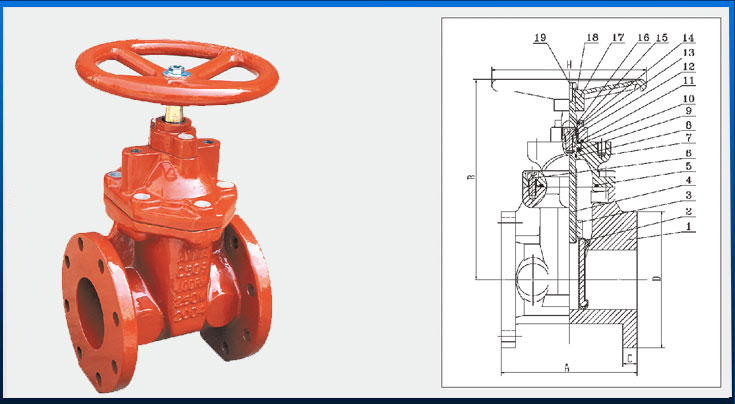

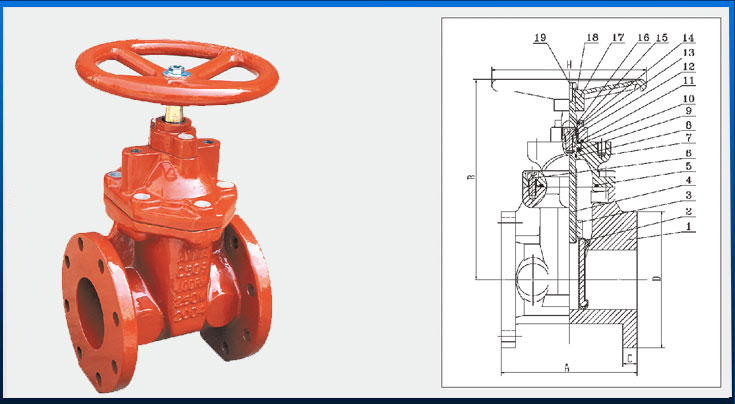

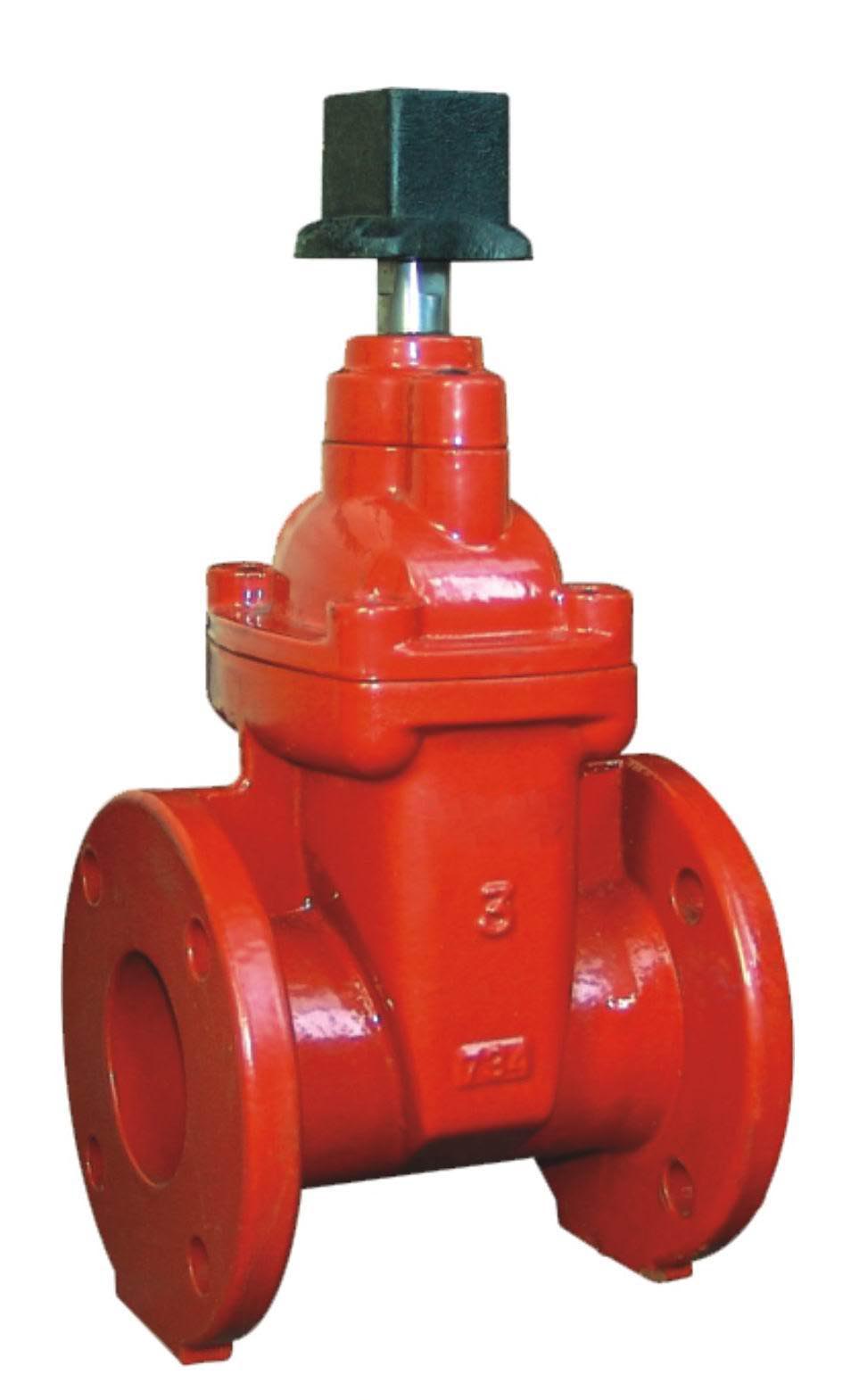

Flanged Ends NRS Resilient Seated Gate Valves-AWWA C509-UL FM Approval – Kingnor Detail:

| Product details: |

| 250 PSI AWWA C509 Iron Body Non-rising Stem Flanged Joint Ends Resilient Wedge Gate Valves |

Bolted Bonnet · Non-Rising Stem · Resilient Wedge · Flanged Ends

250 PSI/17.2 Bar Non-Shock Cold Working Pressure

CONFORMS TO AWWA C509

Coating – Electrostatically applied fusion-bonded epoxy 0.2-0.5mm. inside and outside. Meets or exceeds AWWA C550.Maximum operating temperature 160oF/71oC

Freezing Weather Precaution – Subsequent to testing a piping system, valves should be in an open position to allow complete drainage. |

|

|

|

PART |

SPECIFICATION |

|

1.

|

Valve Body |

Ductile Iron ASTM A 536 |

|

2.

|

Resilient Wedge |

Ductile Iron ASTM A 536/EPDM ASTM D 2000 |

|

3.

|

Wedge Nut |

Bronze ASTM B 584 UNS C83600 |

|

4.

|

Stem |

Bronze ASTM B 150 UNS C61400 |

|

5.

|

Bonnet Gasket |

EPDM ASTM D 2000 |

|

6.

|

Bonnet Screw |

Alloy Steel ASTM A 574M Zinc Plated |

|

7.

|

Bonnet |

Ductile Iron ASTM A 536 |

|

8.

|

Stem Primary O-Ring |

EPDM ASTM D 2000 |

|

9.

|

Stem Thrust Washer (lower) |

Bronze ASTM B 584 UNS C83600 |

|

10.

|

Stem Thrust Washer (upper) |

Stainless Steel ASTM A 276 UNS S41000 |

|

11.

|

Gland Seal O-Ring |

EPDM ASTM D 2000 |

|

12.

|

Stem Seal Bushing |

Bronze ASTM B 584 UNS C83600 |

|

13.

|

Stem Secondary O-Ring (2) |

EPDM ASTM D 2000 |

|

14.

|

Gland Flange |

Ductile Iron ASTM A 536 |

|

15.

|

Gland Flange Screw |

Alloy Steel ASTM A 574M Zinc Plated |

|

16.

|

Stem Ring Wiper |

EPDM ASTM D 2000 |

|

17.

|

Square Operating Nut |

ASTM A 126-B

Cast Iron ASTM A 126-B |

|

17A.

|

Handwheel (Optional) |

Ductile Iron ASTM A 536 |

|

18.

|

Flat Washer |

Carbon Steel Zinc Plated |

|

19.

|

Screw |

Alloy Steel ASTM A 574M Zinc Plated |

|

Size

|

Dimensions

|

Bolt

Circle

|

Flange

Holes

|

Turns

To Open

|

Weight

|

|

A

|

B

|

C

|

D

|

?

|

H

|

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

In.

|

mm.

|

Lbs.

|

Kg.

|

|

2

|

50

|

7.0

|

178

|

10.0

|

255

|

0.63

|

16.0

|

6.0

|

152

|

7.9

|

200

|

4.75

|

121

|

4

|

6.5

|

30

|

14

|

|

21/2

|

65

|

7.5

|

190

|

11.3

|

287

|

0.69

|

17.5

|

7.0

|

178

|

7.9

|

200

|

5.50

|

140

|

4

|

8.8

|

35

|

16

|

|

3

|

80

|

8.0

|

203

|

12.6

|

321

|

0.75

|

19.0

|

7.5

|

191

|

10.2

|

260

|

6.00

|

152

|

4

|

10.6

|

45

|

20

|

|

4

|

100

|

9.0

|

229

|

13.5

|

344

|

0.94

|

24.0

|

9.0

|

229

|

10.2

|

260

|

7.50

|

191

|

8

|

13.0

|

71

|

32

|

|

6

|

150

|

10.5

|

267

|

17.4

|

441

|

1.00

|

25.4

|

11.0

|

279

|

14.8

|

375

|

9.50

|

241

|

8

|

15.6

|

122

|

55

|

|

8

|

200

|

11.5

|

292

|

20.8

|

529

|

1.13

|

28.6

|

13.5

|

343

|

14.8

|

375

|

11.75

|

298

|

8

|

17.3

|

196

|

89

|

|

10

|

250

|

13.0

|

330

|

24.2

|

614

|

1.19

|

30.2

|

16.0

|

406

|

15.7

|

400

|

14.25

|

362

|

12

|

21.4

|

294

|

134

|

|

12

|

300

|

14.0

|

356

|

27.6

|

700

|

1.25

|

31.8

|

19.0

|

483

|

19.7

|

500

|

17.00

|

432

|

12

|

25.3

|

426

|

194

|

|

14

|

350

|

15.0

|

381

|

34.3

|

870

|

1.38

|

35.0

|

21.0

|

533

|

19.7

|

500

|

18.74

|

476

|

12

|

30.0

|

605

|

275

|

|

16

|

400

|

16.0

|

406

|

34.3

|

870

|

1.46

|

37.0

|

23.5

|

597

|

19.7

|

500

|

21.24

|

539.5

|

16

|

34.0

|

800

|

364

|

|

18

|

450

|

17.0

|

432

|

40.1

|

1018

|

1.57

|

40.0

|

25.0

|

635

|

19.7

|

500

|

22.76

|

578

|

16

|

38.0

|

|

|

|

20

|

500

|

18.0

|

457

|

43.2

|

1173

|

1.69

|

43.0

|

27.5

|

699

|

19.7

|

500

|

25.00

|

635

|

20

|

42.0

|

|

|

|

24

|

600

|

20.0

|

508

|

53.9

|

1368

|

1.89

|

48.0

|

32.7

|

831

|

19.7

|

500

|

29.53

|

750

|

20

|

46.0

|

|

|

|

|

|

Product detail pictures:

Related Product Guide:

New Victaulic Gasket for Maritime Industry Simplifies Gasket Specification | Water Pipe Fittings

Industrial zoning OKâd for Complete Fire Protection in Queen Creek | Grooved Flange Adaptor

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for

Well-designed Thread Swing Check Valve -

Flanged Ends NRS Resilient Seated Gate Valves-AWWA C509-UL FM Approval – Kingnor, The product will supply to all over the world, such as: Turkmenistan

, Ecuador

, Nepal

, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

By Polly

from Manila

- 2016.01.28 19:59

By Polly

from Manila

- 2016.01.28 19:59

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

By Patricia

from America

- 2015.09.23 17:37

By Patricia

from America

- 2015.09.23 17:37